Our product portfolio consists of a comprehensive range of high quality, innovative and sustainable raw materials for the Coatings industry.

Our customers prefer to work with us because of our strengths: customer-centricity and deep industry expertise. Focusing on our technical resources to provide raw materials today for the coatings of tomorrow.

In addition to our comprehensive Coatings Industry solutions we are also offering a supplementary pigments portfolio.

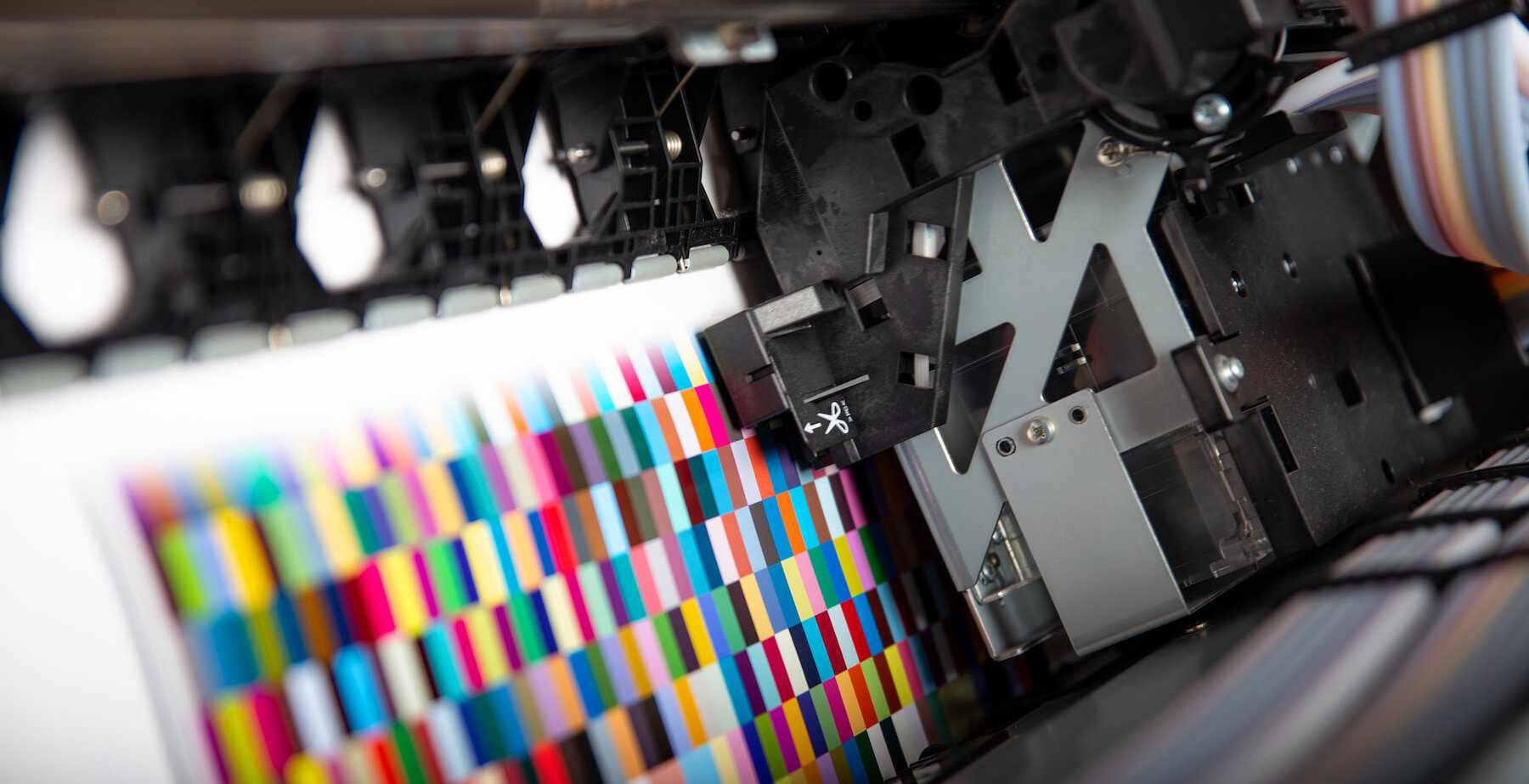

Water-based Inks – The Future of flexible Packaging.

Climate change, population growth and rising pollution levels are putting considerable strain on our planet and resources. In response, more sustainable solutions are required from all areas of business. That’s why BASF is joining forces with pioneers from across the value chain to PRETHINK INK: Together with like-minded partners, we want to tackle today’s and tomorrow’s challenges for packaging. We are convinced that water-based inks are the future of flexible packaging.

Over the past many years water-based inks for flexpack have been trialled, but not often accepted by the market. These last few years the discussion on sustainability has intensified and the need for improved technology has grown to control and reduce the amounts of solvents.

Today the print quality of prints made with WB inks can match the ones printed with SB inks. This is the result of a combination of improved resin technology (new insights and use of new raw materials), formulation knowledge (adhesion promotion, use of optimal additive package), innovations in machine design (mainly drying capacity) and printing process (speed, increased viscosity stability of ink).

LAROMER® Energy curable Resins

LAROMER oligomers and reactive diluents are used in various applications and industries such as printing and packaging, adhesives, transportation and industrial coatings, furniture and flooring, electronics, and special applications. BTC Europe offers a broad portfolio of high quality, high functionality oligomers and monomers for a wide range of formulation requirements.

- Faster curing rates over conventional drying techniques

- Low thermal stressing on substrates

- Good adhesion to a wide range of substrates

- Low energy consumption

- High scratch and chemical resistance

- Reduces the use of volatile organic solvents

Services & Digital Helper

BASF´s Lab Assistant

- Designed to simplify your lab life. – Explore. Formulate. Collaborate.

- Gain all relevant product insights

- Find in-depth knowledge

- Get inspiration to innovate

With MyIndustryWorld, you get a quick and direct access to information, trends and news for BASF dispersions products in the EMEA region.

If you would like to access orders or product-related information & documents, please access ChemShop.